sERvices

Many of our clients are surprised to learn how much we are capable of doing. Don’t see what you’re looking for?

COMPREHENSIVE SERVICES

Tool, Die & Mold Building

From start to finish, we have the equipment and expertise for every step in the precision mold making process, and tool & die design and manufacturing.

CNC Milling/5-Axis

A technique common to the aerospace industry, 5-Axis CNC milling allows for cutting across multiple axes simultaneously, producing precise and intricate parts.

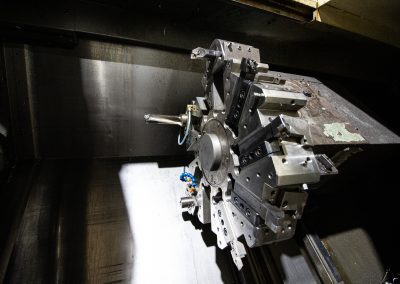

CNC Turning

Using a computer-controlled lathe, we can make any custom part or component to exact measurements.

Wire & Sinker EDM

For hard metals and other materials, wire & sinker EDM cuts intricate contours and cavities without the need for heat to soften and re-harden the material.

Precision Surface Grinding

Our techniques give a more refined finish, while maintaining the closest possible tolerance dimension.

Welding

Our experienced craftsmen have the skills to make a wide range of products with the highest attention to detail.

Jig Grinding

The most effective method of grinding precision holes, our jig grinding machine achieves complex shapes and holes with the highest degrees of accuracy.

Turret Presses

Excellent for punching holes in sheets of metal, this is a process well-suited for mass production.

Laser Cutting

AI-driven fiber laser cutting delivers fast, precise cuts on a wide range of metals with minimal operator input. Ideal for complex shapes and tight tolerances, while reducing energy and gas usage.

Press Brakes

We can bend sheet metal to match any design and purpose.

Tube Bending

We have the capability to bend metal tubes into a variety of designs.

CMM Verification

The CMM is considered an important technique for increasing manufacturing quality.

Sheet Metal Laser

With laser technology, we are able to make custom, complex parts to fit any need.

Mitsubishi GX-F ADVANCED Series Fiber Laser

Our shop is powered by the GX-F ADVANCED Series Fiber Laser from Mitsubishi—an industry-leading system built for precision, speed, and efficiency. With cutting-edge artificial intelligence and automation, this machine delivers high-quality results with minimal operator input.

Key Capabilities:

-

AI-assisted cutting for consistent performance and quality.

-

Automated zoom head adjusts for different materials and thicknesses—no lens changes needed.

-

Up to 77% less nitrogen consumption thanks to AGR-eco gas-saving technology.

-

Cuts material thicknesses from 0.04″ to 1″ with optimized speed and precision.

-

Real-time monitoring of power and gas usage for maximum efficiency.

-

Integrated automation-ready design for faster loading, unloading, and sorting.

Why it matters:

-

45% less energy consumption than traditional CO2 lasers.

-

Reduced operating costs, longer consumables life, and scratch-free surfaces.

Brake Presses

We have a 100-ton and a 200-ton brake press, which allow us to form sheet metal into different shapes and angles. Our tool & die expertise allows us to make any press brake tooling we need to satisfy our customers’ requirements.

Stamping Presses

Our stamping presses utilize complete die sets, which our knowledgeable tool room staff can design and build. These machines mostly use rolled metal and can run some parts in less than one second per part! We can also use these machines for more complex bends that our press brakes cannot achieve.

Turret Presses

We have two turret presses at Advanced Tool & Machine. These machines are one of the most efficient ways to punch and form sheet metal parts.

While we use laser technology for low volume cutouts, the turret press still has the advantage of using forming tools as well as cutting tools for any volume of parts.

Welding

At Advanced Tool & Machine, we have trained professionals who are capable of MIG and TIG welding, as well as brazing, to exact specifications. Whether you need a complex assembly welded or thousands of parts, we have the capability to get the job done right.

Sanding & Finishing

Multiple sanding and finishing machines are utilized at Advanced Tool & Machine to prep parts for whatever finish our customers require.

Full 5-Axis CNC Machining Centers

We have two 5-Axis CNC Machining Centers with the option of a 3rd.

Our ZPS TAJMAC 1210 is a trunnion style machine with a work envelope of 24 x 24 x 24 ( X Y Z ) with a 900-lb weight limit. It has a full 360-degree C axis and 190-degree A axis ( + or – 95 degrees.) Our Deckel Maho DMC60T is a rotary/swivel head machine with a work envelope of 16 x 16 x 16 ( X Y Z ) with an 800-lb weight limit. It has a full 360-degree C axis and 150-degree B axis ( +30 to -120 degrees.) This machine also has a pallet changer, which allows for continuous production runs with no down time for changing parts. The pallet changer can also be utilized to run multiple operations without down time.

We also have a HAAS VF3YT Machining Center with a 5-axis trunnion available, should the need arise for a 3rd 5-axis capable machining center.

3-Axis CNC Vertical Machining Centers

Our multiple Vertical Machining Centers (VMC) range in capacity from 16” x 30” x 20” ( X Y Z ) all the way up to 80” x 30” x 30” ( X Y Z ). This allows us to machine a large range of part sizes.

2-Axis CNC Turning Centers

We have multiple 2-axis CNC Turning Centers. We can turn parts up to 18” in diameter and up to 40” long. Longer parts can be made if they are 3” in diameter or smaller.

Grinding

We have many capabilities for grinding to exact specifications, including: Wet Surface Grinding, Hand Surface Grinding, Jig Grinding, and Centered OD Grinding.

Electrical Discharge Machining

EDM Machining allows for many advantages:

- Ability to cut precisely; Wire EDM Machining can be accurate to +/-.0001” (2.5μm).

- Ability to cut nearly square internal corners.

- Ability to cut tapers that would be impossible to cut otherwise.

- Faster, more accurate production runs.

- Ideal for delicate or intricate parts.

- No burrs are generated.

- Pieces over 10” thick can be machined.

- Tools and parts are machined after heat treatment so dimensional accuracy is held.

- Parts are not affected by heat treat distortion.

We also have a Sinker EDM, which can be utilized when blind EDM is required.